The deep drilling process doen not require any pilot holes or pre-centering. Consequently, the provided material can be delivered with almost no preprocessing. Threads, counterbores and the like should generally be placed after drilling in order to prevent damages.

In order to guarantee highly-qualitative drilling holes, the following special workpiece preparations should be carried though:

Surface marking:

| machined: |  | unmachined (raw/sawn): |  |

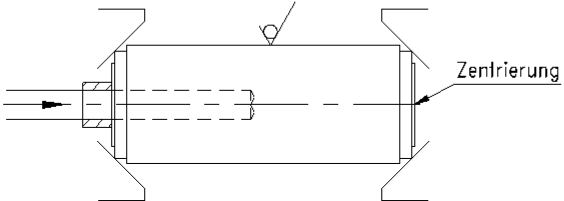

The workpiece is clamped between conical clamping bells. Through elastic force of the clamping procedure, the drill bushing is pressed on. The drilling surface should be turned if possible (at least accurately, orthogonally sawn) without centering and the clamping ends should have a length of 5 mm each and be faced.

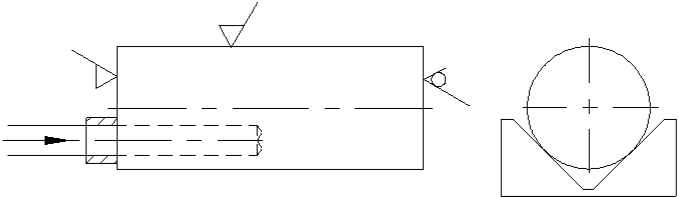

The workpiece is clapmed in prisms and the drill bushing is applied pneumatically. The drilling surface should be turned (at least accurately, orthogonally sawn) and the cylindrically turned on the outside.

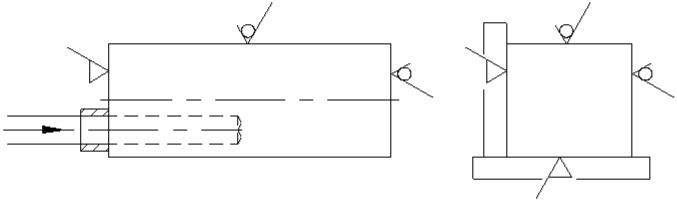

The workpiece is clamped on a flat side and is oriented towards an orthogonally machined surface. The drill bushing is applied pneumatically. The drilling surface should be machined (at least accurately, orthogonally sawn) and the supporting surface as well as the alignment surface should be machined.

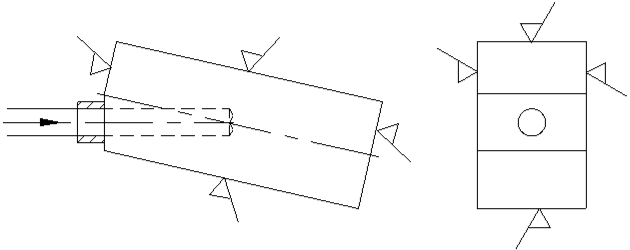

The workpiece is oriented towards the drill axis. For this purpose the workpiece should be machined on all sides if possible (roughened/rough-turned). The drilling surface should be machined in an orthogonal position towards the drill bushing so that the drill bushing can entirely rest againt the drilling surface.

Further questions? Our drilling team is happy to assist you at +49(0)2307/9248437 or via email